Technology Overview

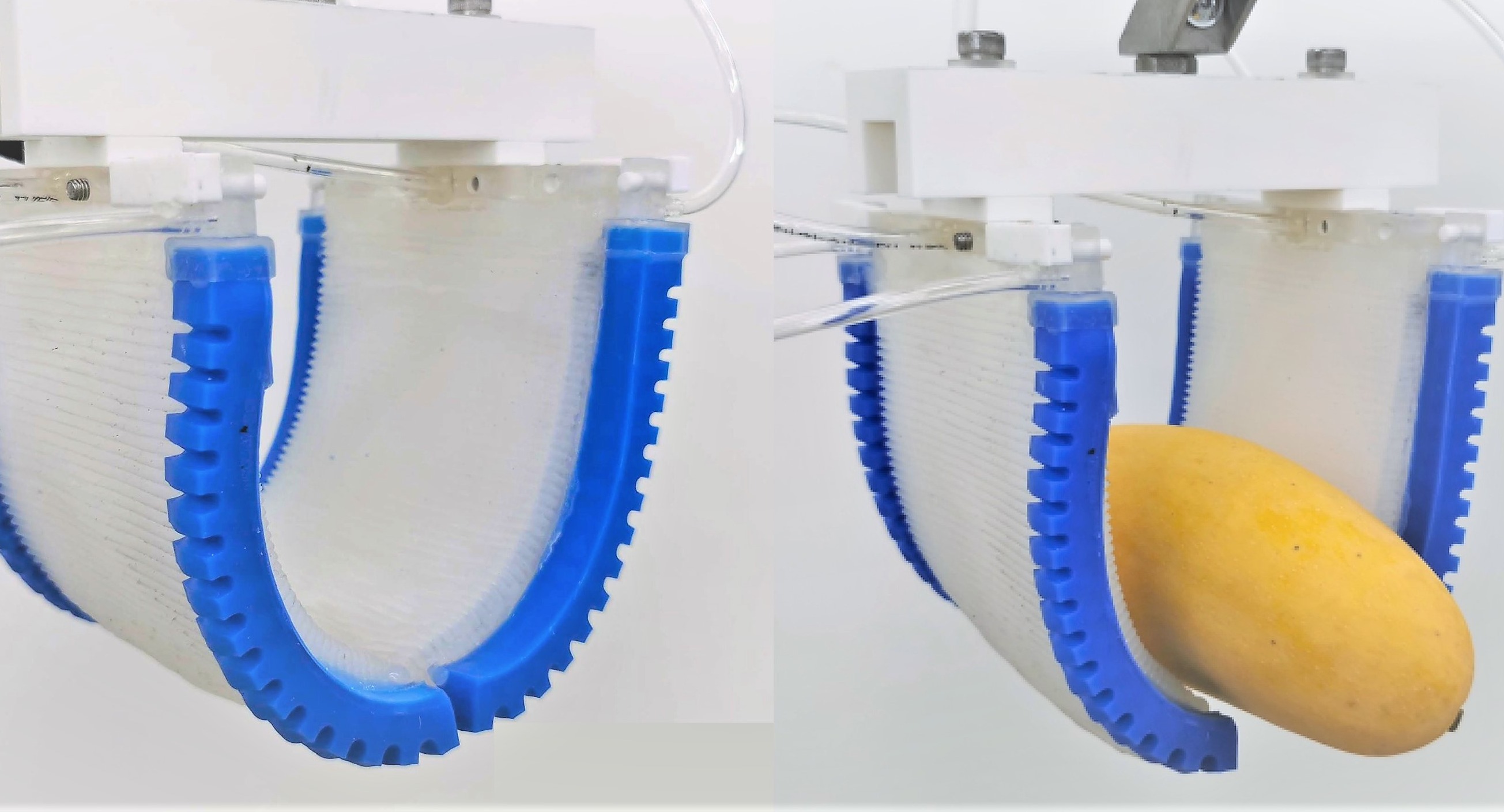

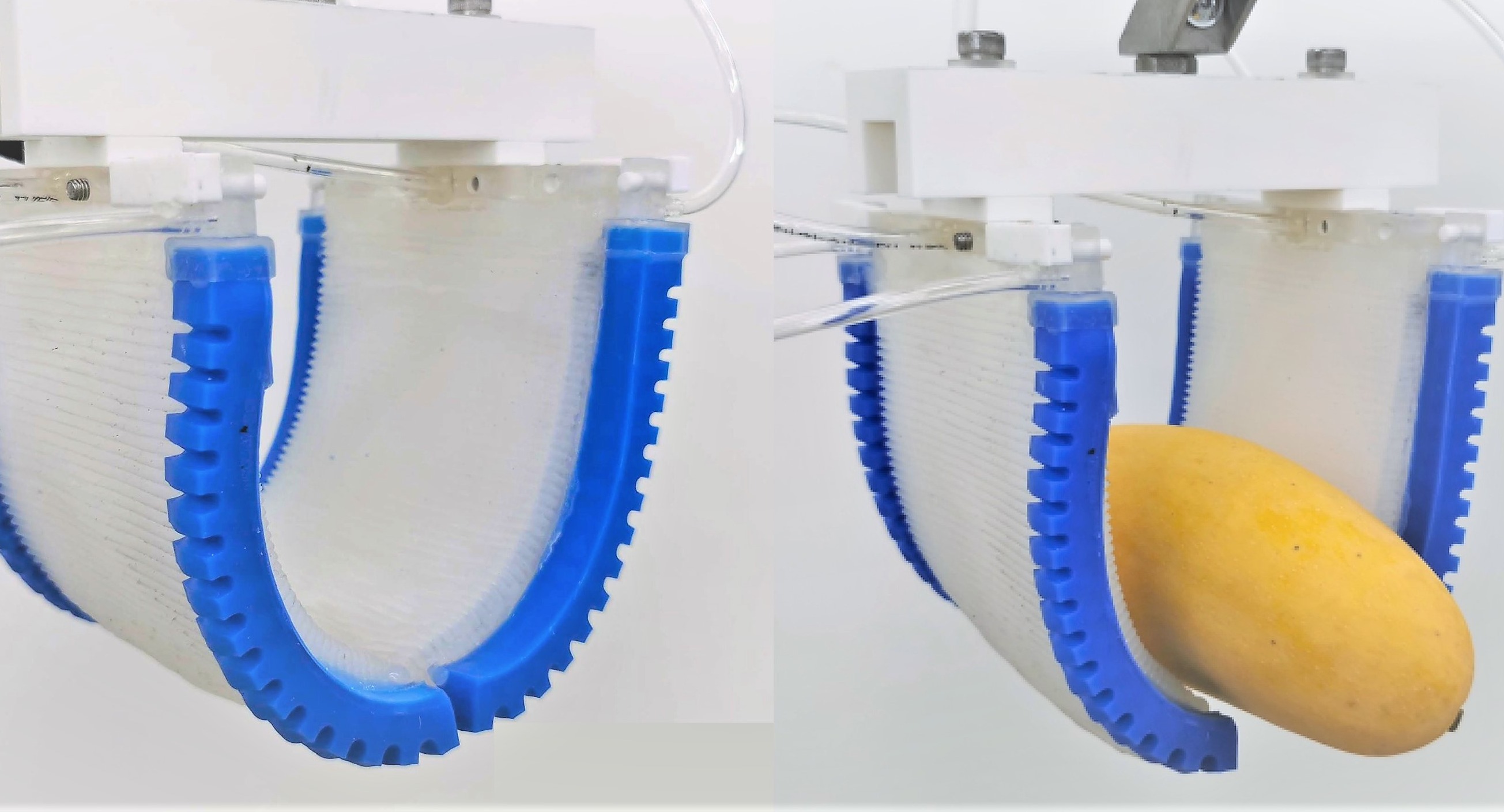

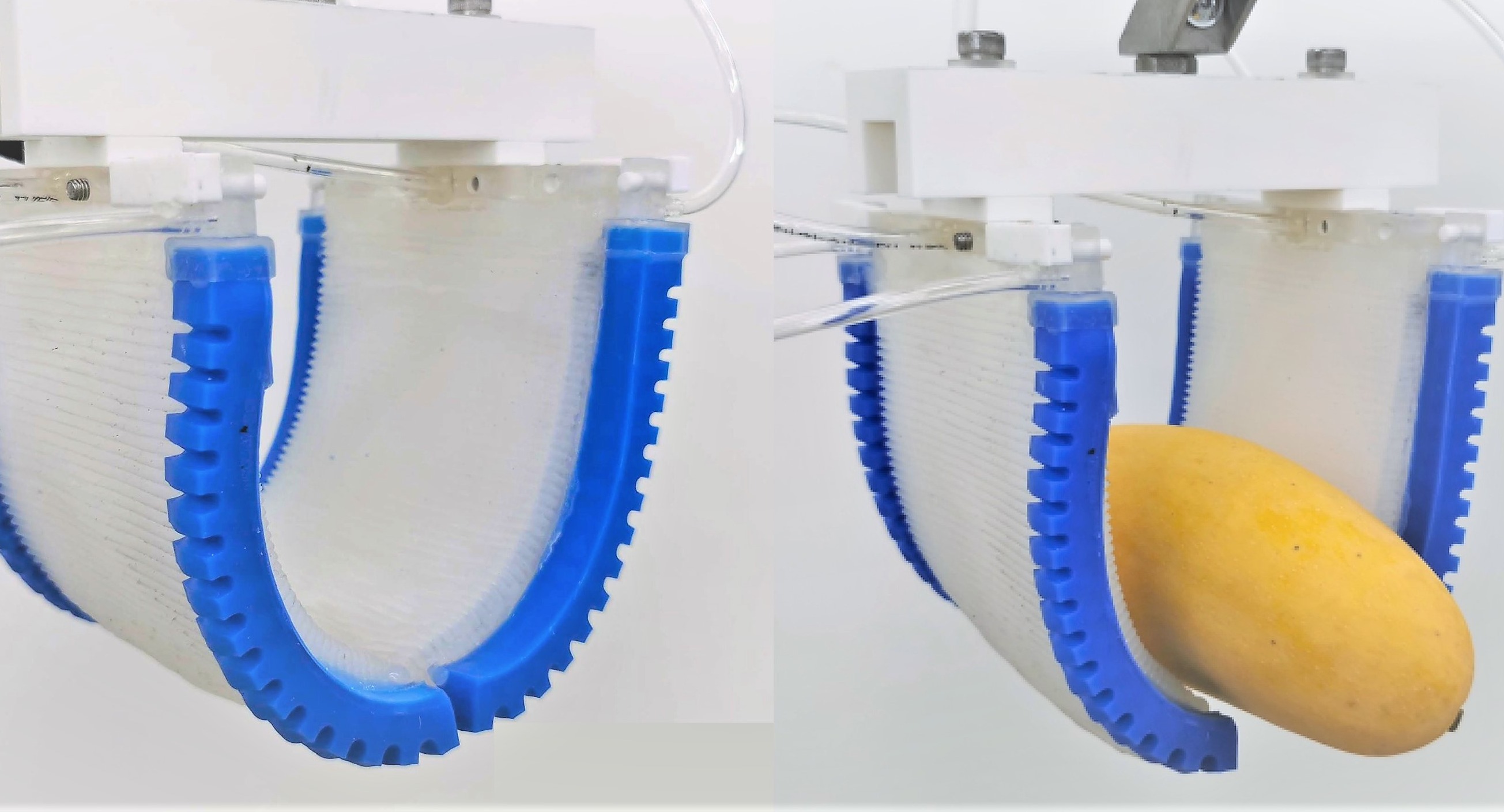

Recent advances in soft robotics revolutionize the way robots interact with the environment, empowering robots to undertake complex tasks using soft and compliant grippers. Compared to traditional rigid structures. Soft grippers have excellent adaptability for a variety of objects and tasks. However, the existing gripper systems faces some challenges, such as handling delicate, wet, and slippery items, the risk of damaging valuable items, and high production cost.Based on pneumatic jamming of 3D-printed fabrics, the technology owner has developed a variable-stiffness soft pneumatic gripper that can apply small forces for pinching and pick-up heavy objects via stiffening. The invented grippers are soft and adaptive to handle delicate items with various shapes and weights, minimising the damaging risk of items during the gripping process. In addition, such gripper with adjustable stiffness could handle heavy and bulky items by increasing its gripping strength. These benefits make the gripper more versatile and adaptable to various applications in agriculture, food processing, packaging, manufacturing, and human-robot interaction (HRI).The technology owner is seeking to do R&D collaboration, IP licensing, and test-bedding with industrial partners intending to integrate variable-stiffness gripper in their applications.

Potential Applications

Agriculture: food harvesting, packaging etc. Food processing: vegetable and fruit picking, food sorting, food packaging, etc. Manufacturing: packaging, assembly, dedicate item handling, etc. Human-robot interaction (HRI)

Customer Benefits

Enhanced robotic performance: universal gripper with high adaptability, versatility, and precision Safe gripping process: good comfortability and high gripping-to-pitch force ratio Cost-effective system: 3D-printed parts assembled with standard components Highly customisable: meet requirements of various industrial applications